Effective project management is crucial in the manufacturing industry. It helps in streamlining processes and improving productivity.

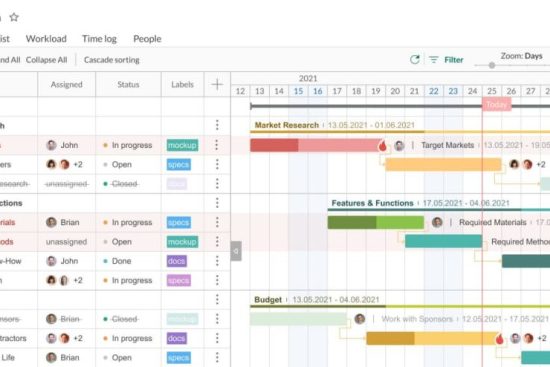

But how can project management software make a difference? In today’s fast-paced manufacturing environment, staying organized is more important than ever. Project management software offers a suite of tools designed to help manufacturers plan, execute, and monitor their projects. This type of software can assist with task scheduling, resource allocation, and progress tracking.

By using project management software, manufacturing businesses can reduce downtime, minimize errors, and ensure that every project is completed on time and within budget. This blog post will explore the features and benefits of project management software tailored specifically for the manufacturing industry. Discover how these tools can transform your operations and boost efficiency.

Credit: www.workzone.com

Introduction To Project Management Software

Manufacturing industries face complex projects. Managing these projects efficiently is crucial. Project management software offers the tools needed to streamline tasks. It enhances productivity and ensures timely delivery. This software caters to the unique needs of manufacturing, making processes smoother and more efficient.

Need For Efficiency In Manufacturing

Efficiency is key in the manufacturing industry. Delays or errors can lead to significant losses. Manufacturers need to optimize resources and minimize waste. This is where project management software comes into play. It helps in planning, scheduling, and tracking progress.

Consider the following benefits:

- Time management: Assign and track tasks to ensure deadlines are met.

- Resource allocation: Allocate resources effectively to avoid overuse or underuse.

- Cost control: Monitor expenses and stay within budget.

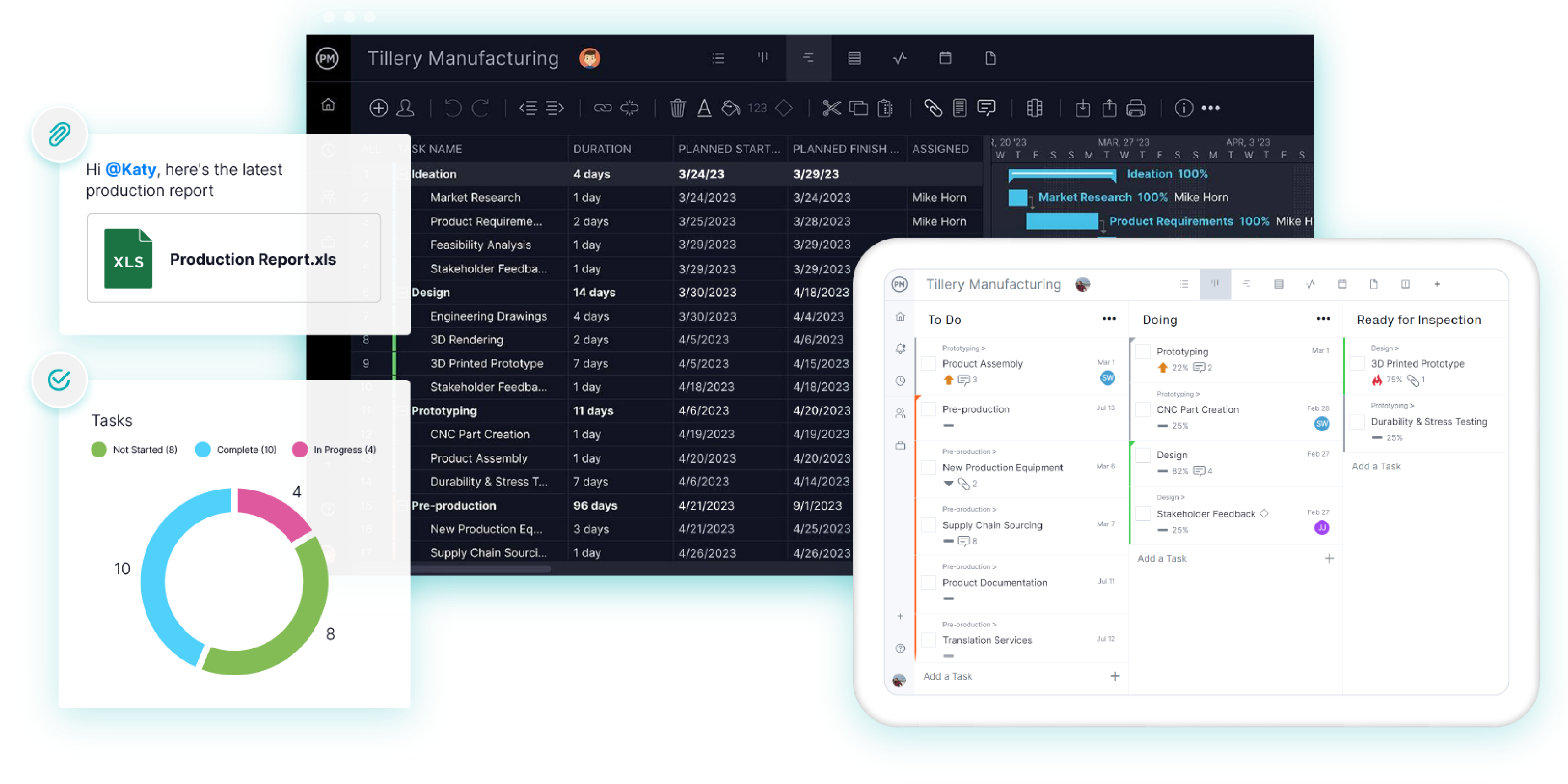

Role Of Software In Modern Manufacturing

Modern manufacturing relies heavily on technology. Project management software integrates various functions under one platform. It provides real-time updates and data analytics. This helps in making informed decisions quickly.

Here is how the software plays a role:

| Function | Role |

|---|---|

| Planning | Create detailed project plans and timelines. |

| Scheduling | Set milestones and deadlines to keep the project on track. |

| Monitoring | Track progress and identify bottlenecks early. |

The software also facilitates communication. Teams can collaborate effortlessly. Notifications and updates ensure everyone is on the same page. This enhances teamwork and boosts productivity.

Credit: thedigitalprojectmanager.com

Key Features Of Project Management Software

Project management software is essential for the manufacturing industry. It helps streamline operations, improve productivity, and ensure timely delivery. Here are the key features of project management software that are crucial for manufacturing:

Task Management

Task management is a core feature of project management software. It allows you to:

- Create tasks and sub-tasks

- Assign tasks to team members

- Set deadlines and priorities

- Track progress in real-time

With task management, you can ensure that every task is well-organized and completed on time.

Resource Allocation

Effective resource allocation is vital in manufacturing. Project management software helps you:

- Allocate resources efficiently

- Monitor resource usage

- Optimize resource distribution

This feature ensures that you make the best use of available resources, reducing waste and boosting productivity.

Time Tracking

Time tracking is another important feature. It enables you to:

- Track time spent on each task

- Monitor employee work hours

- Generate time reports

This helps in managing project timelines and ensuring that projects are completed within the stipulated time frame.

Benefits For Manufacturing Industry

Implementing project management software in the manufacturing industry can bring numerous benefits. It helps streamline operations, reduces costs, and enhances productivity. Below are some of the key advantages:

Improved Workflow

Project management software optimizes workflow processes. This ensures tasks are completed on time and within budget. Managers can assign tasks, monitor progress, and address issues quickly.

Using automated tools, employees can track their daily tasks. This reduces manual errors and saves valuable time. It also helps in identifying bottlenecks and resolving them efficiently.

Reduced Downtime

Downtime can be costly for manufacturing firms. Project management software minimizes downtime by scheduling regular maintenance and tracking machine performance.

With real-time updates, managers can plan maintenance activities without disrupting production. This ensures machines operate at peak efficiency and reduces unexpected breakdowns.

Enhanced Collaboration

Effective collaboration is crucial in manufacturing. Project management software facilitates communication between teams. This leads to improved coordination and faster decision-making.

Teams can share documents, updates, and feedback in a centralized platform. This reduces the need for back-and-forth emails and meetings. It also ensures everyone is on the same page.

In summary, project management software offers significant benefits for the manufacturing industry. Improved workflow, reduced downtime, and enhanced collaboration are just a few of the advantages. Embracing this technology can lead to more efficient and productive operations.

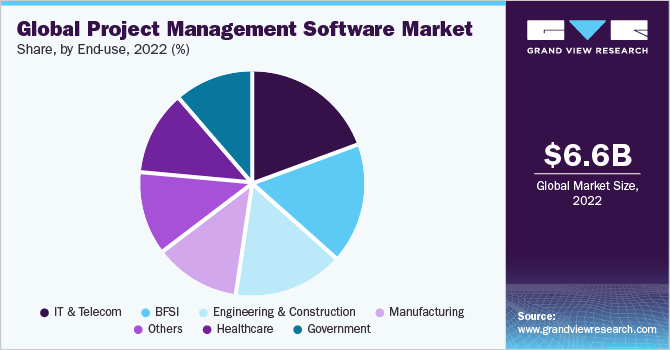

Credit: www.grandviewresearch.com

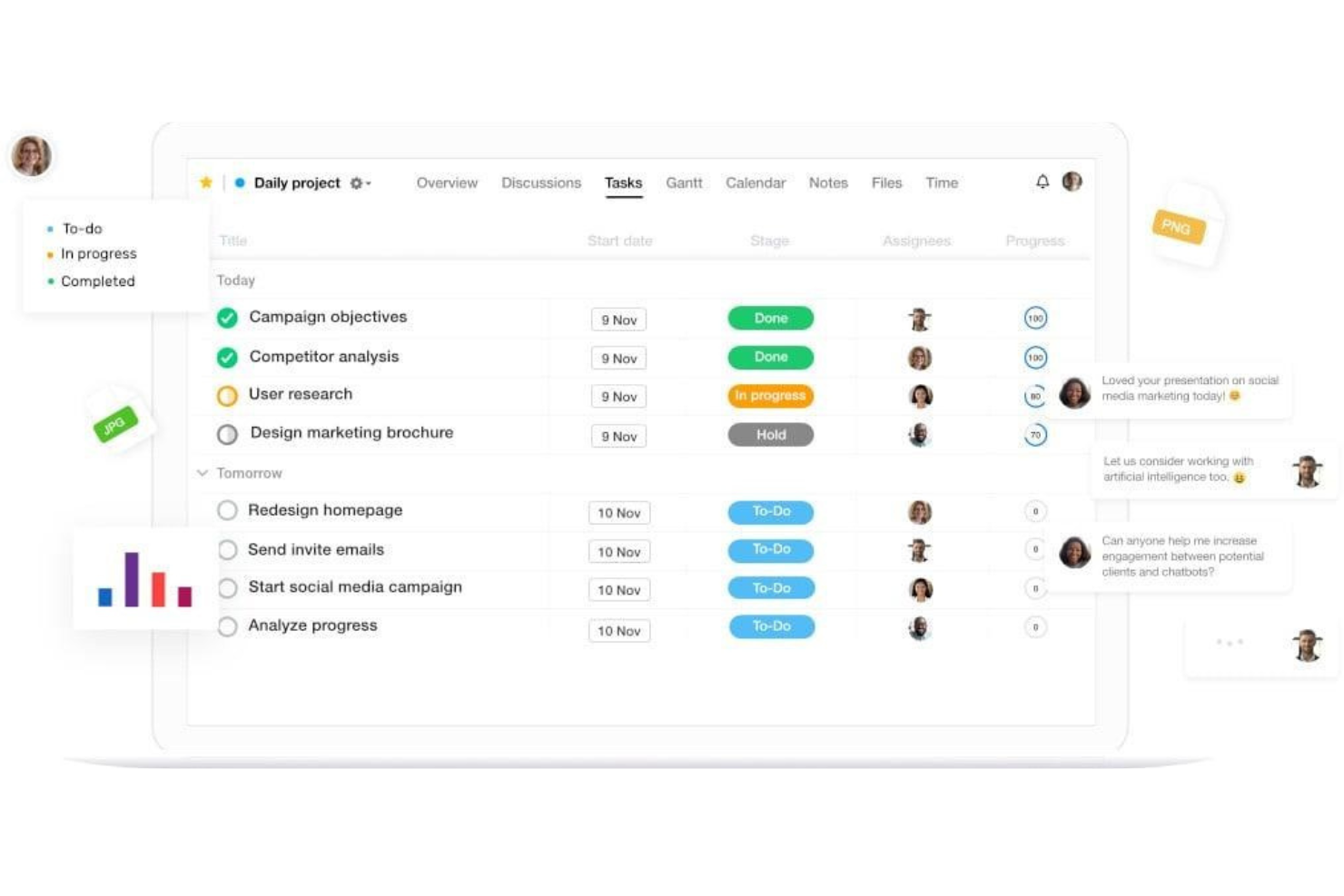

Popular Project Management Tools

Project management software is crucial for the manufacturing industry. It helps manage complex processes, streamline workflows, and ensure timely deliveries. Here, we explore some popular project management tools that can enhance productivity in manufacturing.

Tool A Overview

Tool A is known for its user-friendly interface. It offers robust features that cater to the needs of the manufacturing industry. Key features include:

- Real-time project tracking

- Resource management

- Gantt charts for scheduling

- Task dependencies

This tool helps teams stay on top of their tasks and deadlines. It also offers integration with other essential tools.

Tool B Overview

Tool B excels in customizability. It allows manufacturers to tailor the software to their specific needs. Important features include:

- Custom workflows

- Inventory management

- Time tracking

- Collaboration tools

Tool B ensures that all team members are on the same page. It is a versatile tool for managing various aspects of manufacturing projects.

Tool C Overview

Tool C is ideal for large-scale manufacturing projects. It provides advanced analytics and reporting. Some standout features are:

- Advanced project analytics

- Risk management

- Budget tracking

- Automated alerts and notifications

This tool helps in making data-driven decisions. It ensures projects stay within budget and on schedule.

Implementation Strategies

Implementing project management software in the manufacturing industry requires a strategic approach. Effective implementation ensures the software enhances productivity and streamlines processes. This section explores key strategies for successful implementation.

Training And Onboarding

Effective training and onboarding are crucial. Employees must understand how to use the new software. This involves:

- Initial training sessions

- Ongoing support

- Regular feedback

Consider creating step-by-step guides. Use video tutorials for more complex tasks. Ensure everyone feels comfortable with the new system.

Integration With Existing Systems

Integration with existing systems is vital. The software must work seamlessly with current tools. Key steps include:

- Assessing compatibility

- Data migration planning

- Testing integration

Ensure no data is lost during integration. Test thoroughly before full-scale implementation. This prevents disruptions in production.

Customization Options

Every manufacturing business is unique. Customization options allow the software to meet specific needs. Important customization aspects include:

| Aspect | Details |

|---|---|

| Templates | Pre-defined templates tailored to your processes |

| Modules | Choose modules relevant to your operations |

| Permissions | Set permissions based on roles |

Customizable software adapts to your workflow. This boosts efficiency and user satisfaction.

Challenges And Solutions

The manufacturing industry faces many challenges in adopting project management software. Businesses often struggle with resistance to change, data security concerns, and scalability issues. Below, we dive into these challenges and explore solutions.

Overcoming Resistance To Change

Many employees resist new software because they fear the unknown. To ease this transition:

- Provide thorough training sessions to employees. This will build confidence and competence.

- Communicate the benefits clearly. Explain how the software will make their tasks easier.

- Involve team leaders in the process. They can motivate others to embrace change.

Regular feedback sessions can also help. Listen to concerns and address them promptly.

Ensuring Data Security

Data security is crucial in the manufacturing industry. Protecting sensitive information is a top priority. Here are some solutions:

- Use strong encryption methods to protect data.

- Implement multi-factor authentication to prevent unauthorized access.

- Regularly update software to fix vulnerabilities.

These steps will help keep your data safe and secure.

Scalability Concerns

As your business grows, your software must scale with it. Consider the following:

| Solution | Benefit |

|---|---|

| Cloud-based software | Easy to scale up without hardware investments. |

| Modular architecture | Allows adding new features as needed. |

| Regular performance reviews | Ensures the software meets growing demands. |

Choosing the right software with these features will ease scalability concerns.

Case Studies

In the manufacturing industry, project management software can be a game-changer. It enhances efficiency, tracks progress, and ensures timely delivery. Let’s explore some real-world applications through case studies. These examples will show how different companies have benefited from using project management software.

Successful Implementation In Company X

Company X, a leading car parts manufacturer, adopted project management software to streamline its production process. They faced challenges such as delayed timelines and miscommunication.

- Implemented software to manage schedules

- Centralized communication channels

- Integrated inventory management

Within six months, Company X saw a 20% increase in on-time project delivery. The software helped in reducing miscommunication and ensuring everyone was on the same page.

Efficiency Gains In Company Y

Company Y, a producer of electronic devices, used project management software to improve their production efficiency. They wanted to reduce downtime and increase output.

| Metric | Before | After |

|---|---|---|

| Production Downtime | 15% | 8% |

| Production Output | 1000 units/day | 1200 units/day |

Company Y’s software solution streamlined their processes, reduced downtime, and increased output. They achieved a 12% improvement in overall efficiency.

Lessons Learned From Company Z

Company Z, involved in heavy machinery manufacturing, faced several issues during their software implementation. They learned valuable lessons along the way.

- Start Small: Begin with a pilot project.

- Training: Invest in training for all employees.

- Feedback: Continuously gather feedback to improve the system.

Company Z realized the importance of taking small steps and ensuring everyone was on board. They successfully integrated the software, leading to smoother operations.

Future Trends

The manufacturing industry is rapidly evolving. Project management software is crucial for staying competitive. Future trends in this software are transforming how manufacturers operate. Let’s explore these trends.

Ai And Machine Learning

AI and machine learning are reshaping project management. These technologies can analyze vast amounts of data quickly. They can predict outcomes and suggest improvements. This means more efficient and accurate planning. AI can also automate repetitive tasks, freeing up human resources for critical thinking tasks.

Iot Integration

IoT integration is another significant trend. It connects machines and devices to the internet. This allows real-time data collection and monitoring. IoT can help in tracking inventory, monitoring equipment performance, and predicting maintenance needs. This leads to reduced downtime and increased productivity.

Predictive Analytics

Predictive analytics is transforming decision-making in manufacturing. It uses data, statistical algorithms, and machine learning techniques. This helps in forecasting future outcomes. Predictive analytics can identify potential risks and opportunities. It ensures that projects stay on track and within budget.

Frequently Asked Questions

What Is Project Management Software For Manufacturing?

Project management software for manufacturing helps manage tasks, schedules, and resources. It enhances efficiency and productivity. This software streamlines workflow, minimizes errors, and ensures timely project completion.

How Does Project Management Software Benefit Manufacturing?

It improves task management, resource allocation, and communication. It also reduces delays and enhances productivity. This leads to higher efficiency and cost savings.

Can Small Manufacturers Use Project Management Software?

Yes, small manufacturers can use project management software. It helps streamline processes, improve task management, and boost productivity. It is scalable for any business size.

What Features Should Manufacturing Project Management Software Have?

Key features include task tracking, resource management, scheduling, and collaboration tools. It should also provide real-time updates and reporting. Customization options are essential for specific needs.

Conclusion

Adopting project management software transforms manufacturing processes. It boosts efficiency and reduces errors. Teams collaborate better, leading to higher productivity. Time and resources get optimized. This software makes tracking progress easy. Decisions become data-driven, improving overall outcomes. Investing in the right tool fosters growth.

Manufacturing businesses stay competitive and meet customer demands. Simplify complex tasks with project management software. Embrace technology for smoother operations. The right software supports your goals. Start benefiting from improved project management today.